Can we make biogas from our food waste?

ToolNatural

More Information

Our current food waste situation

Created 2yCreated over 2 years ago

We are now around 25 people and generate around 3 - 5 kg a day of food waste. For the last 2 years, we have been composting our food waste in a simple open-air structure. So far, it is working well and it doesn't require much attention besides pouring our food waste every day on top, stirring it weekly, and every now and then turning it upside down. We alternate between 2 piles to let it compost. When one of the piles is ready, we use it for little projects on the land.

Loading...

Loading...-18a4745f9dc.jpeg?width=1280&resize=contain)

Loading...

Loading...-18a4745f9dc.jpeg?width=1280&resize=contain)

Loading...

Loading...-18a474623a6.jpeg?width=1280&resize=contain)

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...-18a4745f9dc.jpeg?width=1280&resize=contain)

Our current gas situation

Our actual buthane gas consumption is divided into 2 different stations. We use propane to heat water for showers and to cook. We use 11 l butane bottles

We have one bottle attached to each fire pit for cooking, as shown in the images. We spend around 3 bottles every month for cooking. With this gas consumption, we can feed 25 people daily for breakfast, lunch and dinner.

For showering, we used to have an electric boiler that we run on solar power, but it did not have enough water and consumes a lot of energy. So last year, we installed a backup boiler to have hot water for all the kampers, which also runs in propane. So basically, all our hot water is coming from the gas boiler. For this, we use around 2 bottles a month. Yes, 25 people sweating in a dusty environment means a lot of showers a day.

Overall, we are spending 5 gas bottles a month.

Loading...

Loading...-18b43e86b22.jpeg?width=1280&resize=contain)

Loading...

Loading...-18b43e86b22.jpeg?width=1280&resize=contain)

Loading...

Loading...

Loading...

Loading...-18b43e8f57a.jpeg?width=1280&resize=contain)

What we want to solve

So far, we have been using propane to cook and shower, but there are more sustainable solutions. Our food waste stream just leads to a pile of compost that we don't use much, so now we want to go one step forward to capture the gas produced by the bacteria that decompose our food waste and make use of it.

It seems complex to use biogas for water boilers. We would need a very specific boiler to be able to use it.

On the other hand, the option of trying to cook with it seems more doable. So that's what we want to go for, we want to explore if we can cook with biogas made on our land. We are still not sure what would be a doable amount to produce in our setting, but that's what this research is about.

Loading...

Loading...

Options for commercial Biogas systems

Setting up a biogas system in our setting raises up many different questions, such as:

Which scale do we want to go for? How much gas do we want to get? How much food can we process with a biogas system? Can we easily implement it in our setup? Does it have an easy maintenance? Is it scalable?

These and many other questions were raised for us in order to continue our research. We have found different options and commercial companies already working with these systems, as you can see in the images and the following links:

https://www.homebiogas.com/

https://biogaspuxin.es/

But are these systems really working? Can we learn from them?

The positive points are that the technology and hardware for them seem already developed and working. But for us, it seems still too green the project to be able to know and choose one of these systems that would last for the future.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

DIY Biogas systems

Another great option out there is the DIY Biogas system. Materials and technology related to these systems are not set in stone; luckily, many options are available on the internet.

You can find several options in Instructables, YouTube, and websites. There are a lot of people around the world trying to solve the same problem in different ways.

These systems used to have some points in common like:

Build with conventional materials

Low expertise requirements

Flexibility in the pieces and connections

Low tech

Low cost

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

IBC Biodigester

A specific biodigester that caught our attention was the option built in an IBC container. IBC containers are largely extended in our area so it is a very common material around us. The rest of the pieces are also available around us in local plumbing shops.

This IBC biodigester was developed by a project called Solar Cities. They have a lot of open-source documentation, training and resources to develop these biodigesters and extend their use in the world.

We chose this option for several reasons:

We want to build the system ourselves to help us understand the technology better. When we know the technology and see its possibilities, we can make better decisions in order to implement it in the future on a larger scale. We also want to analyse the outcome, difficulties and needs for such systems, and we think the better way to do it is to build it ourselves and start to work with it.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Our biodigester explained

Inside the biodigester happens different processes in order to produce gas out of our food waste. It is basically works as a animal stomach digesting organic matter and creating CH4 gas and biofertilizer.

In the first image you can see the layers inside the biodigester. Each of the pipes reach a different layer having its own mission.

Feeder goes to the bottom laying the organic matter.

Biofertilizer pipe goes to the middle of the IBC. This allows the biodigester releasing pressure by pouring the biofertilizer outside.

Gas outlet is in the top of the IBC to harvest the gas with lower density than the rest of the layers.

Watch the next video of Solar Cities to have a better explanation of it

https://www.youtube.com/watch?v=bzCQudIQaqk&list=PLpOiXXbeG7n_LLkbpBSraCRFFNOcLx6TV&index=2&ab_channel=SolarC%C2%B3ITIES

Loading...

Loading...

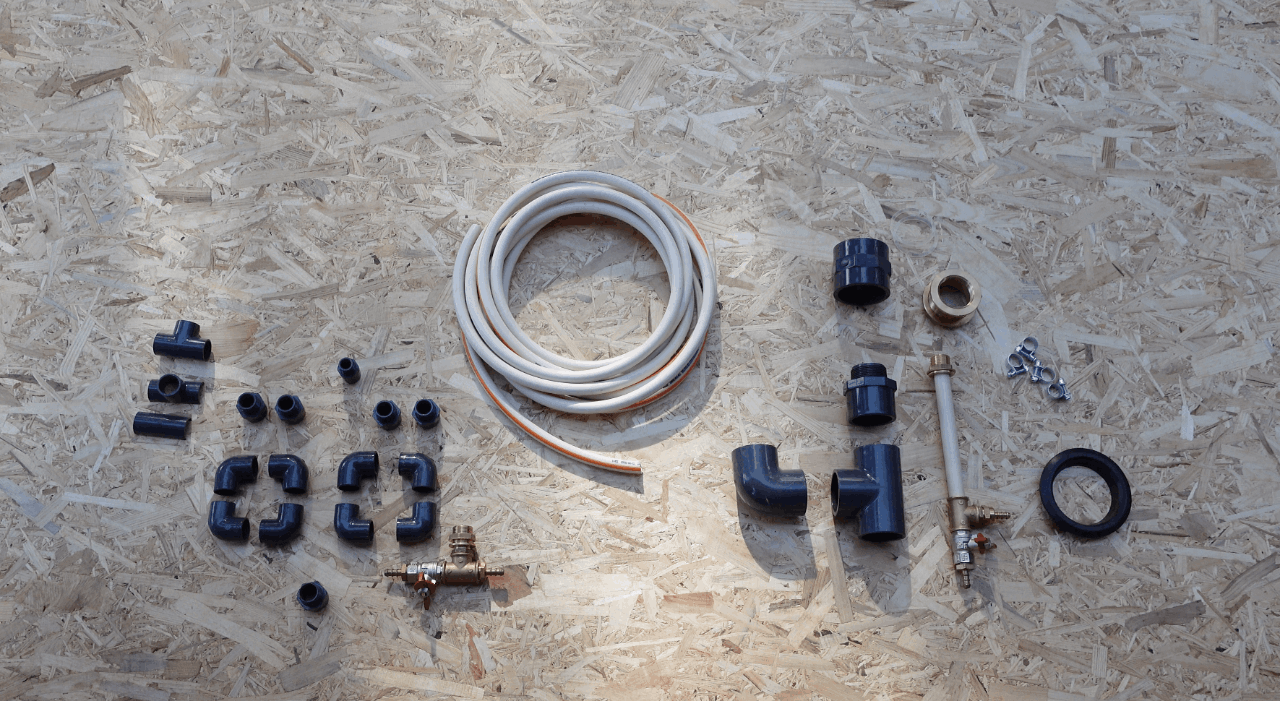

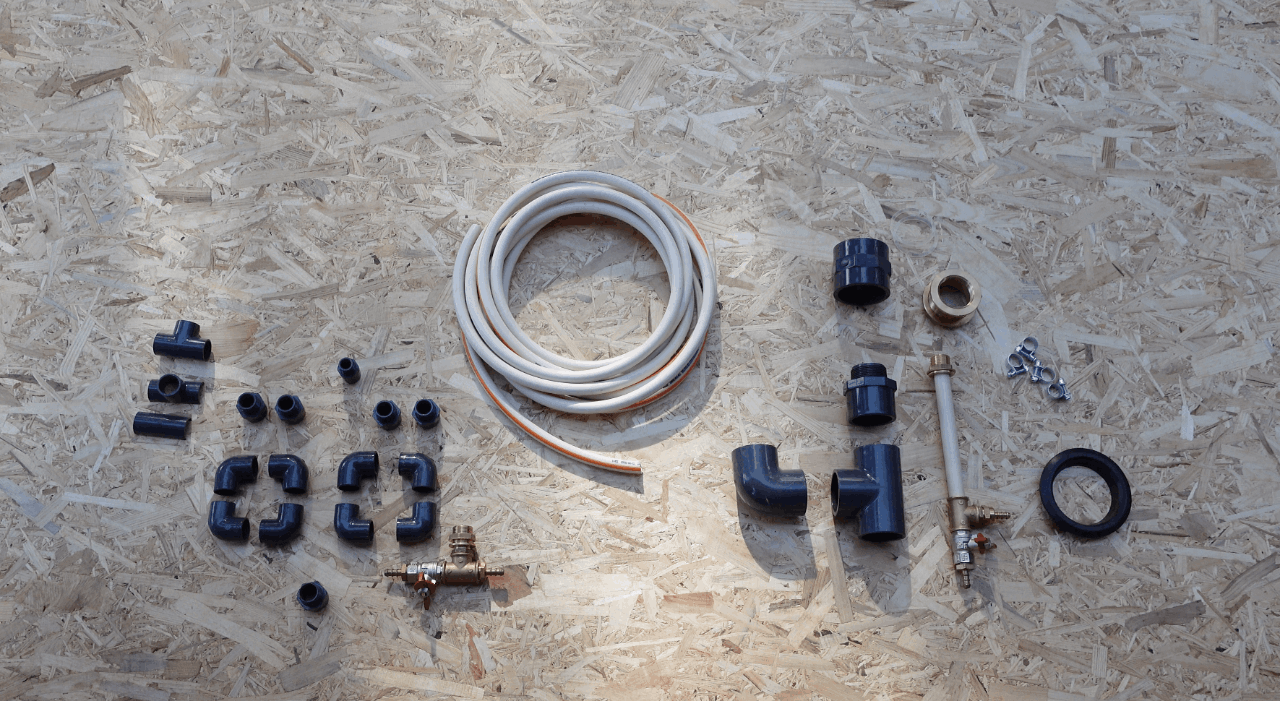

Our prototype parts

In the image you can see all the pieces used to build our prototype. The main parts needed for our biodigester are the following:

1 m² IBC tank black painted to avoid light to go in (important to not let algae grow in and produce O2)

220l Blue barrel

120l Blue barrel (this barrels should fit into eachother)

Feeding PVC pipe with great diameter, ours is 90mm

Fertilizer PVC pipe with smaller diameter, ours 50.

PVC T and 90° elbow connection for the outlet of the biofertilizer

Fittings for the pipes in the IBC and gasometer. We have used uniseal for the feeder and threaded brass conections for gas and biofertilizer

Valves to coordinate and control gas flow

Connectors between pipes and hoses

Gas hose (fermenter – gas storage, gas storage – stove)

Total cost of the parts is around 200€

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Our prototype built

We finally built our prototype. Our system is based on an IBC biodigester from SolarCities with a gasometer made with Fabio from Favela da Paz.

The biodigester is the stomach of our system, where the magic happens. Food is dumped here, gas and biofertilizer are the outcome of it.

The gasometre is where we store our gas. The gasometer is made with the 2 blue barrels open and fit into each other, then we fill it with water in order to seal the gas inside the one that is inside the other upside down.

From min 5:18 to min 19:43 of our 100 update you can see how we built it

Loading...

Loading...

Gas production challenges

We have started our biodigester system with cow poop, as you have seen in the video. The recomendation is to start slowly with what we called "baby food". So far we have been feeding our biodigester 1 time a day with a mix of sugars and carbohydrates. Mainly leftovers of porridge, rice and fruit mixed with water and all shredded. What we called baby food for our recently made biodigester.

We have noticed that so far is not producing the right amount of gas. The tank is building pressure inside but the gas coming is not the right one, it is smelly and doesn´t hold a flame. This could be for the concentration of other gases such as CO2 and H2S (this makes our gas stinky) due to the acid PH (less than 6.2)

Next step will be to start to feed it with green leaves in order to stabilize the PH to encourage the bacterias responsible of the Metanogenesis to start produce CH4

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...-18b43ed5167.jpeg?width=1280&resize=contain)

The biodigester of last season and its problems

What is left over?

A filled biodigester and an empty gasometer that could not produce or store gas to create a flame (see Fig:1).

Why did it not work?

Leaks:

- The connection to the gasometer was just a brass thread screwed into a plastic hole without gaskets and Teflon (Fig:3.1).

Incorrect Height of In- and Outlet Pipes:

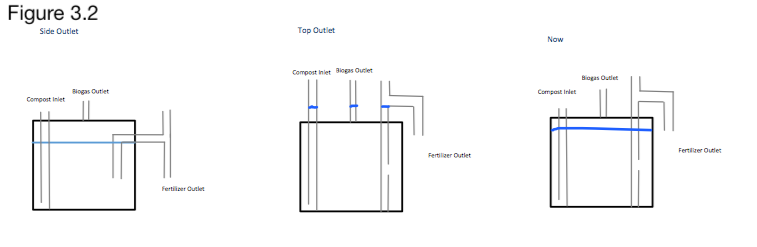

- There are two main types of designs when using IBCs or plastic drums:

1: Fertilizer outlet pipe on the side (Fig: 3.2 "Side outlet").

2: Top inlet and outlet pipes, with the fertilizer overflow lower than the compost inlet and gas outlet (Fig: 3.2 "Top Outlet").

- Last season, a "Top Outlet" design was built with the overflow higher than the inlet (Fig: 3.2 "Now" & Fig: 1).

- Gas production should still work, but only one batch is possible, no continuous overflow.

Light entering the digester

- Because the IBC container was removed from the metal bars, painted, and then placed back into the metal bars, some of the paint was scraped off (see Fig: 3.3)

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

The restart of the project

Created 1yCreated over 1 year ago

Since last season's biodigester project failed to produce a flame, the research project is restarted.

What are the steps?

1. Empty the current load

2. Weigh the food waste that can be used for the biodigester

3. Paint the biodigester

4. Buy new materials

5. Build a new design

6. Place the biodigester in the sun

7. Pressure test and seal if necessary

8. Prepare cow manure

9. Fill biodigester

10. Document conditions: PH, temperature

11. Test flame

There are still a few unanswered questions in section 6. Addressing these issues would be very helpful.

1: Would the old biodigester with this design produce biogas if everything else was right?

2: Why does the biogas in the "Top Outlet" design not leave the liquid through the inlet or outlet of the fertilizer outlet?

3: Does the higher surface area of the liquid in the "Side Outlet" design affect the amount of biogas that exits through the gas outlet?

4: What are the advantages of “Side Outlet” and “Top Outlet” design?

Loading...

Loading...

Testing (and waiting) for the flame

Created 1yCreated over 1 year ago

The following tasks have been completed:

1. Drained the current load

- almost completely emptied

2. Weighing the food waste that can be used for the biodigester

- 2 kg of compostable kitchen waste per day

3. Painting the biodigester

- see Fig 3 Before & After

5. Buy new materials

- Build a new design

6. according to “Side Outlet” post 11 & 12

- see Fig 5

7. Place the biodigester in the sun

- see Fig 5

8. Pressure test and seal if necessary

- screwed joints were replaced with silicone

9. Prepare cow manure

- see Fig 7

10. Fill biodigester

- filled 10 cm under overflow

- approx. 400 l cow manure + 380 l water

11. Document conditions: PH, temperature

- PH: 6,5 (inlet), 7,4 (outlet); T = 39°C

12. Flame test

- No flame after 3 days, probably too much CO2

Question: How long does it take to produce enough methane for a flame?

Note: The balloon is only for the experimental phase. When the flame is obtained, a gasometer will be installed.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

We have a flame!

Created 1yCreated over 1 year ago

After just 8 days of waiting, we successfully achieved a flame. The methane-to-carbon dioxide ratio in the biogas was high enough to ignite.

Our next step is to integrate the biogas into our energy system. We plan to use it for heating water for tea or coffee, which will help us reduce our propane consumption during cloudy days. To do this, we have a modified gas stove, as the ratio of fuel gas to air needs to be higher for biogas. Unfortunately, it doesn't work with biogas as it currently stands.

You can see the stove in figures 2 to 4. It appears that the air inlet has been widened, and one of the nozzles is missing.

Do you have any advice on how to modify this stove so that it works with biogas?

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

The stove works! - How to improve the system?

Created 1yCreated about 1 year ago

Thanks for all your helpful comments!

The stove is now working and has a stable flame. We use it to make coffee, boil water, and heat leftovers.

The gasometer fills up one and a half times a day by feeding about 15 kg of kitchen waste per week. Putting weight on the top of the gasometer only increases the pressure and the stored gas slightly. Because of the limited time, an extension of the storage is planned for next season. This gasometer stores gas for cooking for 25 minutes.

Water collects in the hose from the gasometer to the valves at the biodigester, causing an uneven and unstable gas flow. By lifting it, the water can be drained.

Questions for you:

1. At the moment we sort the food waste well according to the recommended inputs, e.g. no woody waste like nut shells, no coffee, no citrus, less green vegetables. What would be the consequences of feeding all our kitchen waste (coffee, egg shells, nut shells, cabbage)?

2. How big do you think the gas storage should be and how should it be built? (For example, compressed gas in gas bottles or IBC for storage)

3. How to keep high temperature in the biodigester during cold days? (Other than greenhouse enclosure)

4. When and why are filters useful?

5. Do you have any other tips for improvement?

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Can we keep the biodigester alive during winter?

Goopy Fabinho, the biodigester, produces a lot of gas, which helps us to reduce our consumption of fossil fuels.

We would like to use it again next season, but there are some concerns about its life in winter...

Goopy's temperature is getting lower and lower. As you can see in the second picture, it is only 20°C now, in October. It will probably drop below 10°C or 5°C during the winter like this.

Also, there will be fewer people here (probably only 2), so there will be less kitchen waste available.

Is there any way to keep it alive?

A greenhouse would help, but I don't think the labour and environmental costs would be worth it.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...