Can we make a roof from recycled plastic?

Building

More Information

Make a drawing

Created 3yCreated almost 4 years agoUpdated 3yUpdated almost 4 years ago

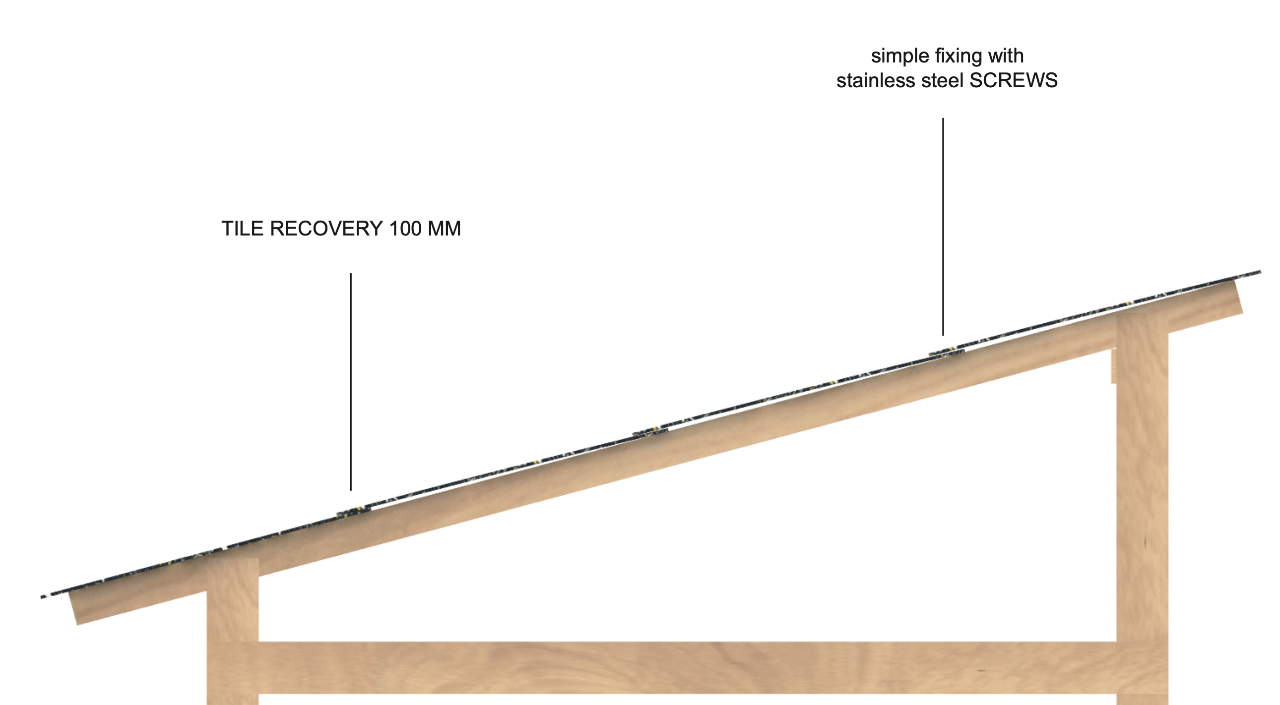

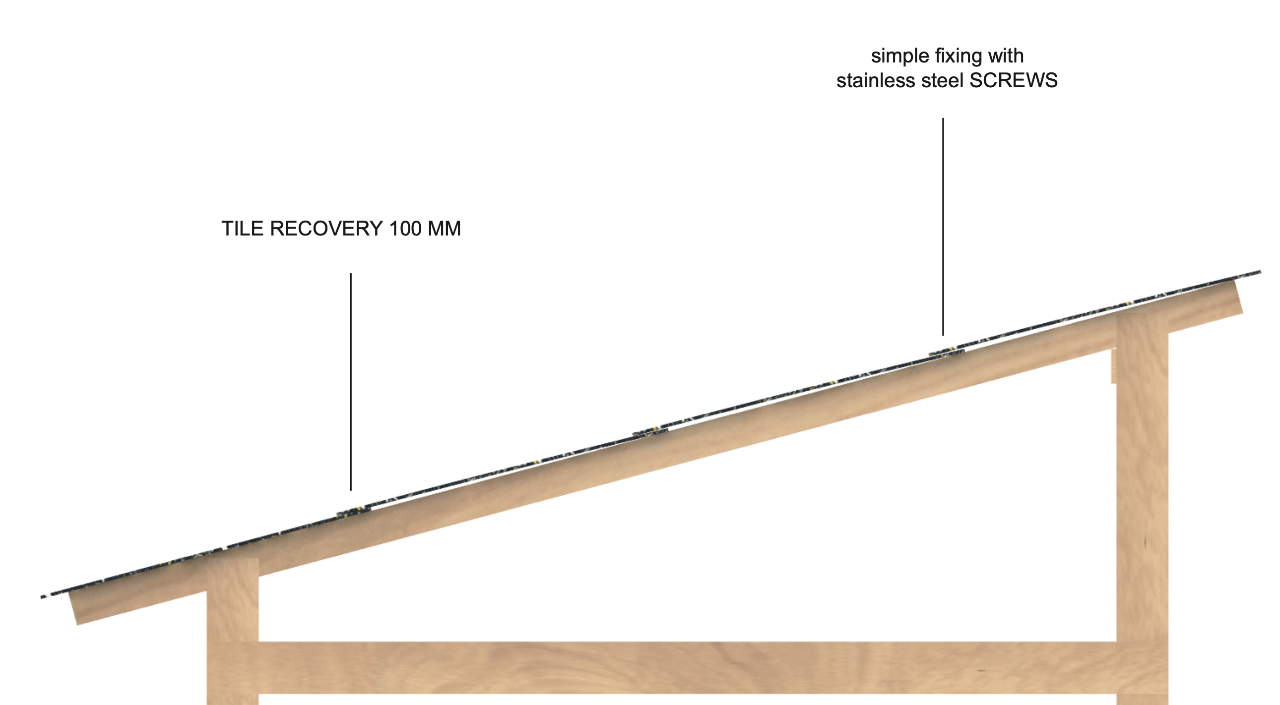

We made a drawing for our structure, it's all based around the size of the sheets, since they are limited to the size of the sheetpress. The frame underneath can easily be adapted to it since it's made in wood and comes in various sizes. The sheet overlap vertically 10CM and horizontally with a 2CM. The small overlap which will be CNC cutted.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Plastic sheets arrived!

Created 3yCreated almost 4 years ago

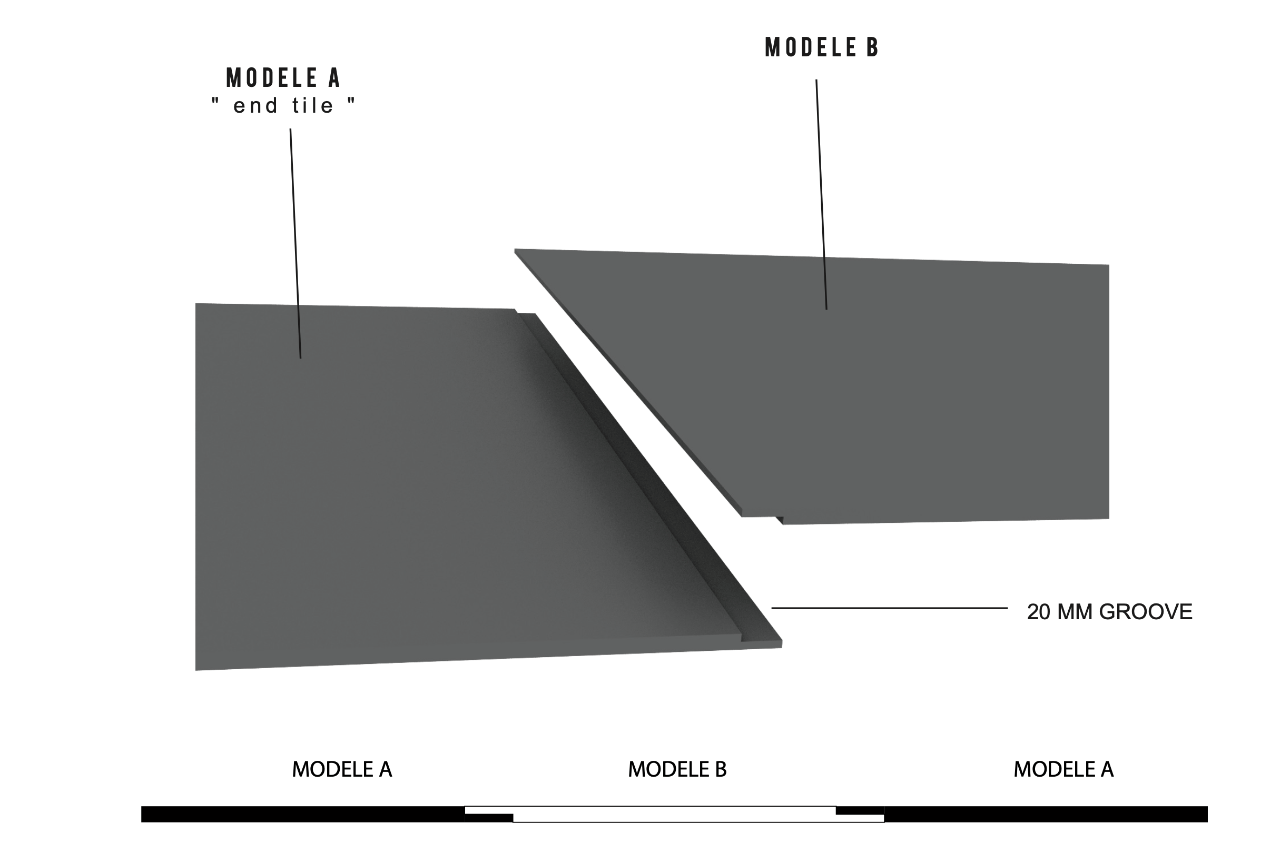

We got our sheets from Fabunit, a Precious Plastic workspace. The sheets are 10MM thick, from Polypropylene and 98x98CM (The edges are cleaned from a 1x1M sheet) They have a groove milled on the sides to make them able to overlap.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Building the structure

Created 3yCreated almost 4 years ago

We build the structure for the roof from Cedar wood. It has 4x7=28 sheets. Installing the sheet was the easy part. Since it just contains a few screws. When putting up the sheets you already noticed a bit of difference in warping because somewhere in the sun. We are thinking of applying UV coating to some area to see the difference overtime.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

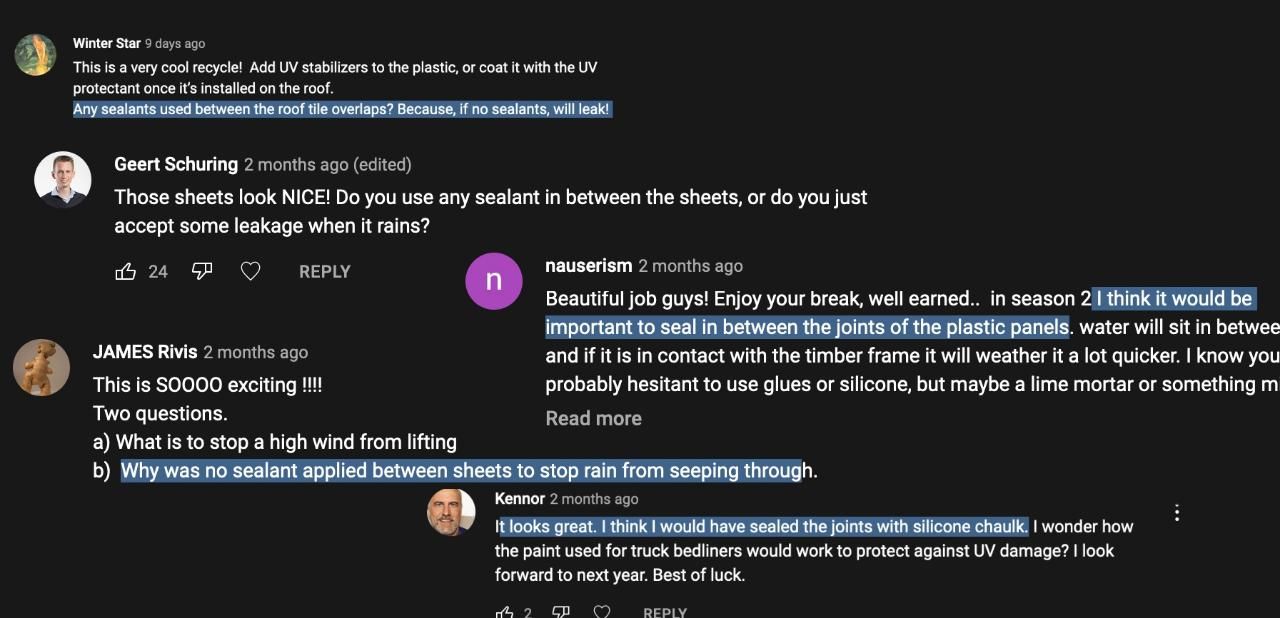

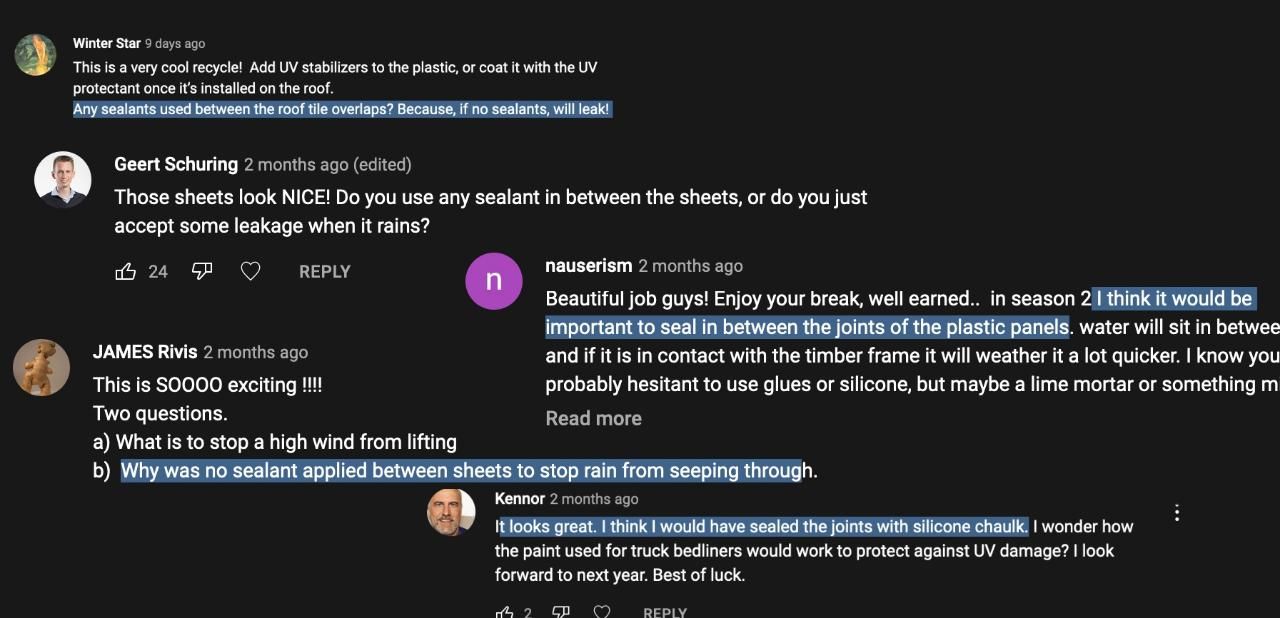

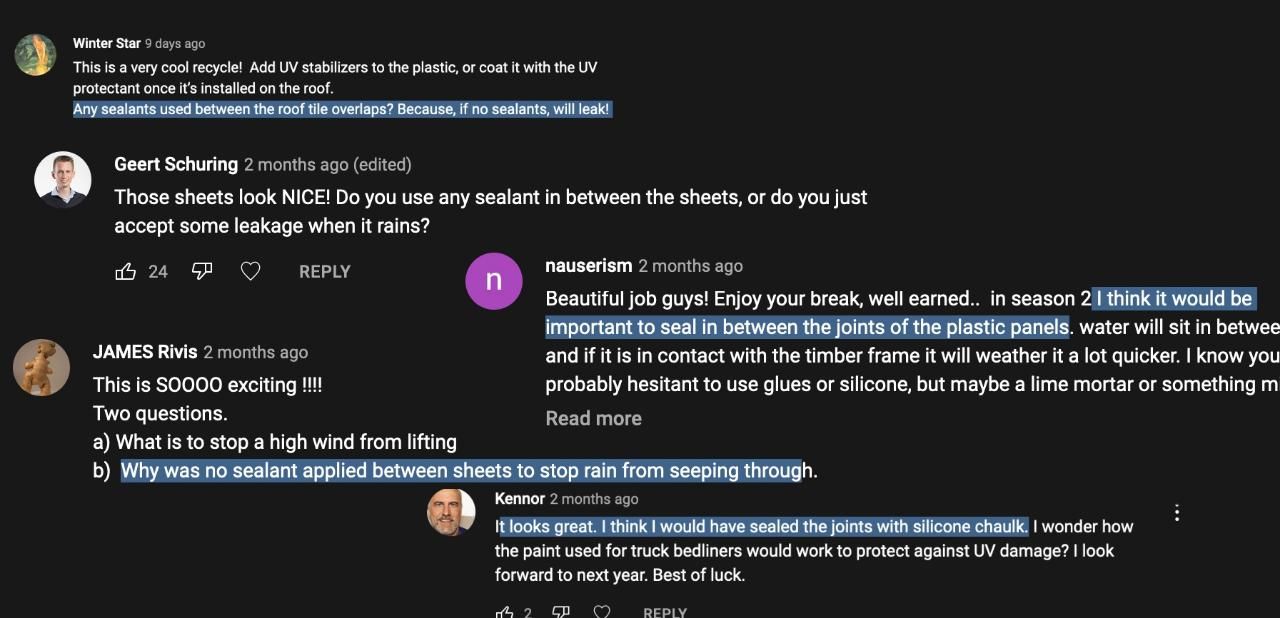

Problems mentioned by Youtube

Created 3yCreated almost 4 years agoUpdated 3yUpdated almost 4 years ago

The roof is a big tryout for us. Funny thing of developing publicly is that you get comments, from all angles. The main two remarks for this videos is that:

1. We have to keep an eye on UV degradation (we were aware of this)

2. The overlap between the sheets isn't enough and will leak. (this we were not)

We're not that experienced making roofs (yet), specially with plastic sheets. But after looking into it more it does seem we missed an overlap or sealant to make sure the tiles don't leak. We are going to keep an eye on it to see how it goes. But for now it's been surprisingly sunny and dry. ☀️

We will share result with the next rain.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Yep, rain leaks on the overlap

Created 3yCreated over 3 years agoUpdated 3yUpdated over 3 years ago

After some intense rain we noticed the roof leaks in some areas where the sheet overlap. It's dripping on those areas but only on a few places and not all edges. Its not much, but very unwated since it never feels safe to put something underneath. Next we are going to try and seal the sheets together. They are made from polypropylene so it's not easy to find a sealant that sticks to it. Let us know if you have any suggestions

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

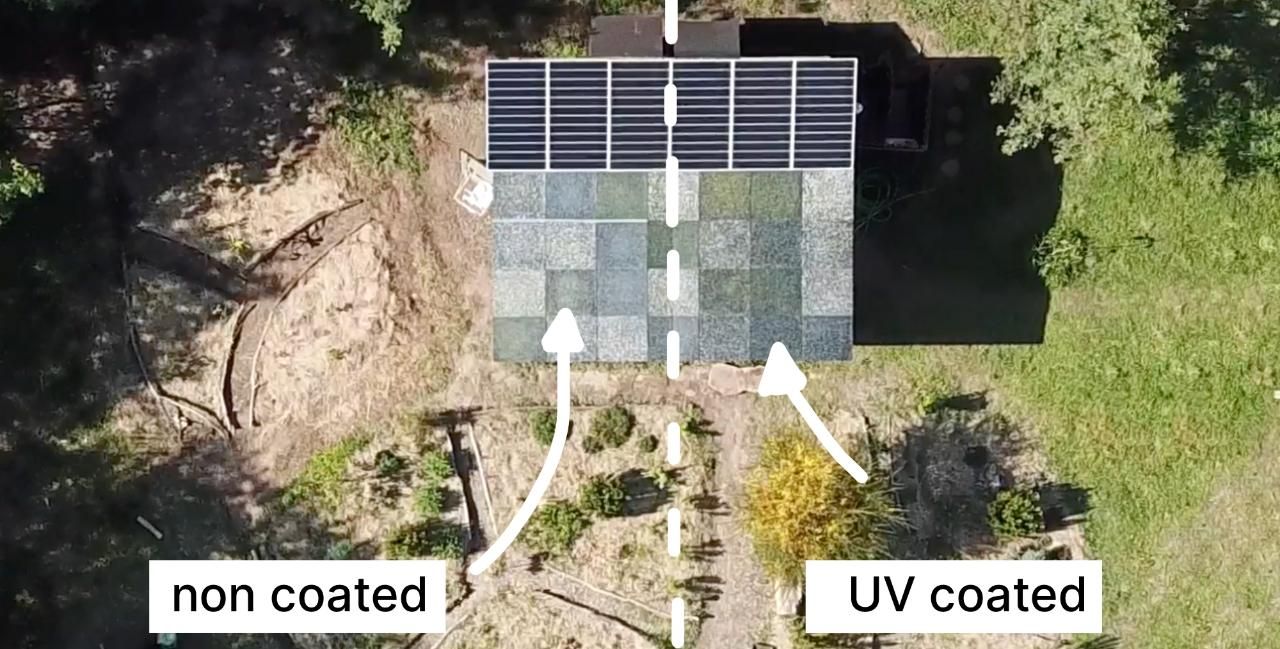

Added UV Coating (half of the roof)

Created 3yCreated over 3 years agoUpdated 3yUpdated over 3 years ago

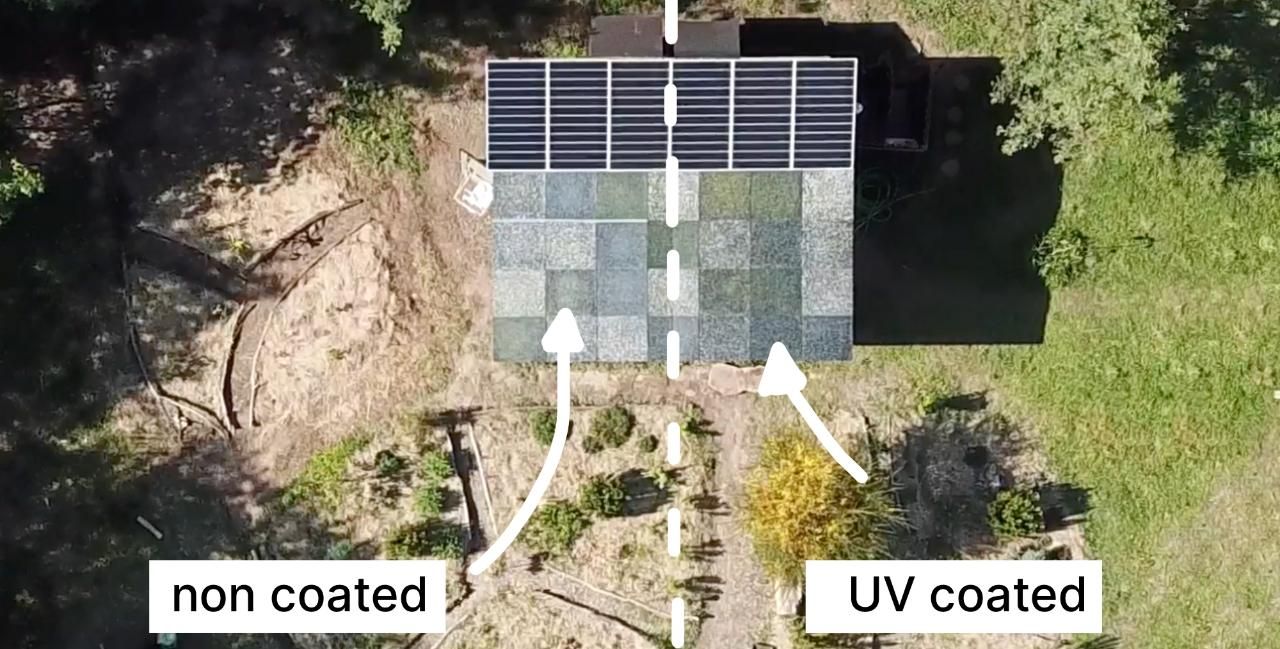

For the sake of experimenting, we've added a UV coating on the half of the roof. We took the entire roof off (also to fix some leaks) and applied the coating to the right side of the roof. It was a 2 component coating that was easy to apply with a roller. This will be a long term experiment to see how it behaves and degrades overtime in the sun. So next time you see a video with a drone shot, make sure to keep an eye on the roof to spot the difference.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Butyl and MS Polimer to stop leaks

Created 3yCreated over 3 years ago

This step was painfull, it felt like a poor fix. Yes. We have finally gone for Butyl paste in the overlaps of the sheets and MS Polimer on top of the overlaps.

Butyl is not a glue itself, it works just as a sealant not holding together the sheets, for holding them together we use some screws (tough task with the warping of the roof). That´s why we decided to add MS Polimer for car windscreens on the top of the overlap, this should still allow the warping of the sheets, keeping us dry underneath.

We've closed all the vertical lines, not the horizontal ones since that should be covered by the sheets overlapping

Let's see how it goes

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

UV coating 2 months later

Created 3yCreated over 3 years ago

We were flying the drone to record some shots and figure lets have a look at that plastic roof with the UV coating on top. We got quite surprised by the visual difference between them after only a few months. You can really see the difference with UV coating on top! Right is with UV coating, left without.

(the weird line in the middle is because we made a mistake swapping the sheets around (:

Loading...

Loading...

Yep, the roof still leaks

Created 3yCreated about 3 years ago

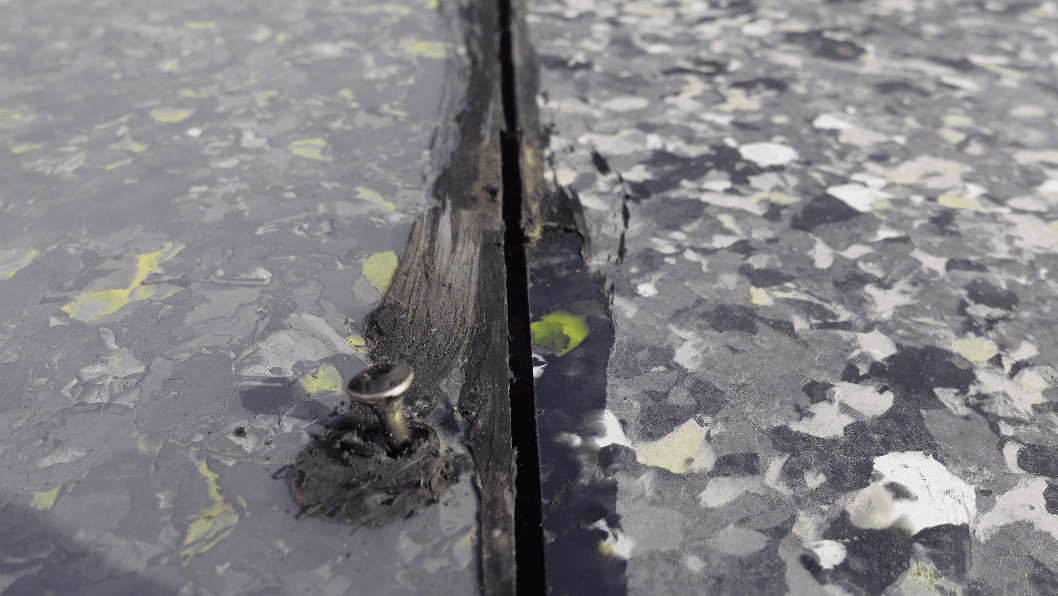

After a long period without rain we didn´t notice much but in the last days rain finally came and the roof start to leak again.

On one side Polypropylene is quite a peaky plastic when we talk about glue and bonding products, not many products can stick to it, we knew that this MS Polymer used for car windshields could fail, but it was our best shot at that time to keep the sheets together.

On the other side, butyl just works if the parts are really together. In this case, MS Polymer didn´t work and the screws either. Not chemical nor mechanical bonding. The warping is caused due to the difference in temperatures which made the plastic sheets move a lot and let our connections be exposed again. Leaving us with a bunch of broken screws and some holes in our “waterproof” connection.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Facade tape for leaks

Created 3yCreated about 3 years agoUpdated 3yUpdated about 3 years ago

After feeling the last leaks in our heads, we have search a bit more and we have found a new product we want to try out, it is called Tyvek tape. This is a tape specially made for outdoors and with high UV resistance. It´s a facade tape that is supposed to stick very well to everything and with a very long-lasting life.

We put it over the grooves where we suspect most of the leaks are coming.

Let´s see how it goes.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

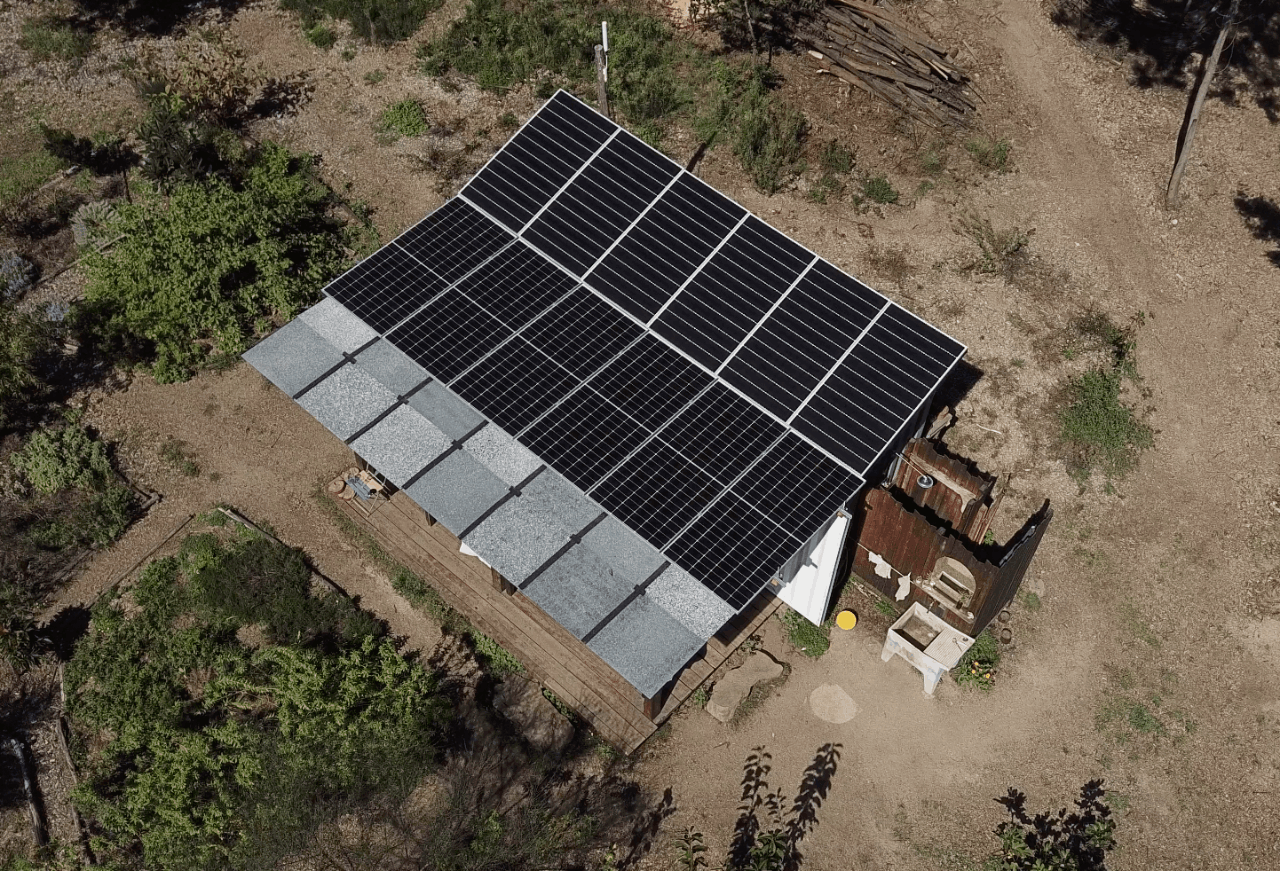

Partially cover with Solar panels

At the end of the summer of 2023 we partially covered the plastic roof with solar panels. The reason behind was to increase our solar production capacity due to shortages of electricity at some points of the year.

We also thought that leaks would be partially solved after covering the plastic sheets with the solar panels. Letting the water collected by the solar panels on the container run over the new ones instead of running on top of the plastic roof.

Real fact, it didn´t work and we still have a lot of leaks under our roof.

You can see how we install them in the following link:

https://youtu.be/66mUbPHkmP0?si=0v01hKeKQo5I9Skc&t=1197

Loading...

Loading...

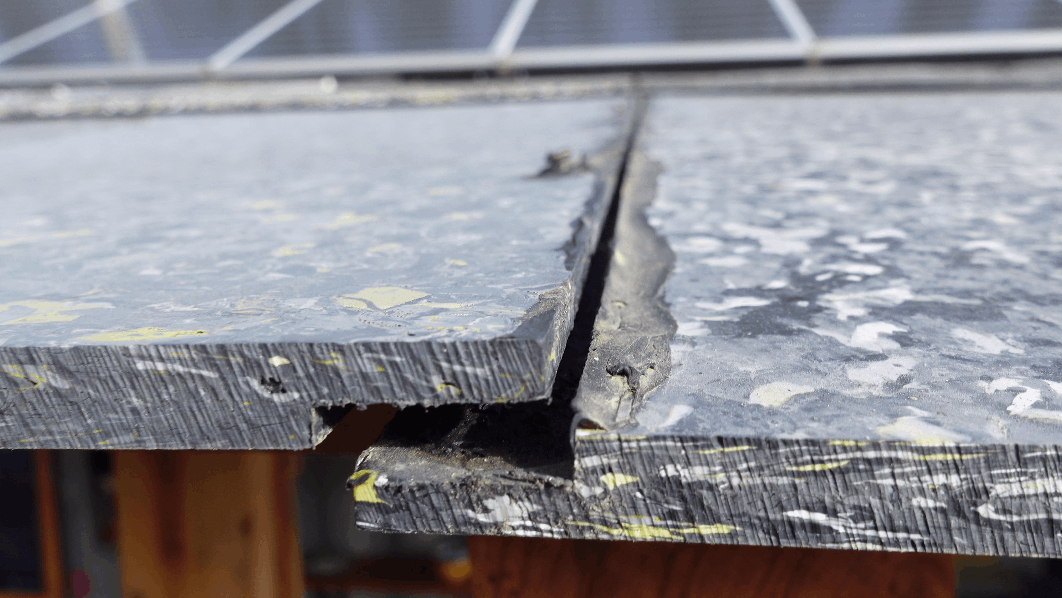

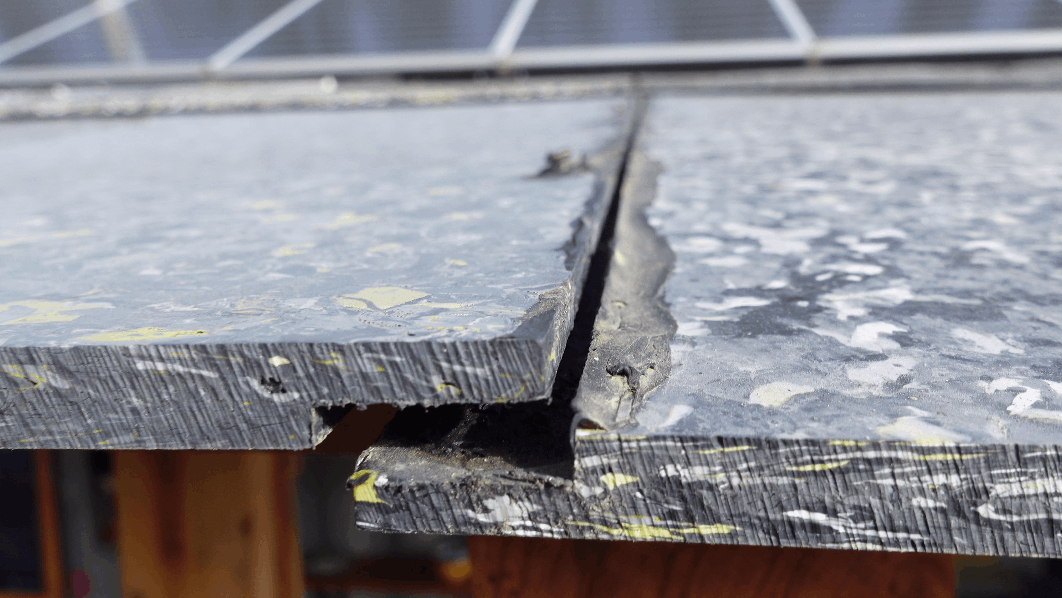

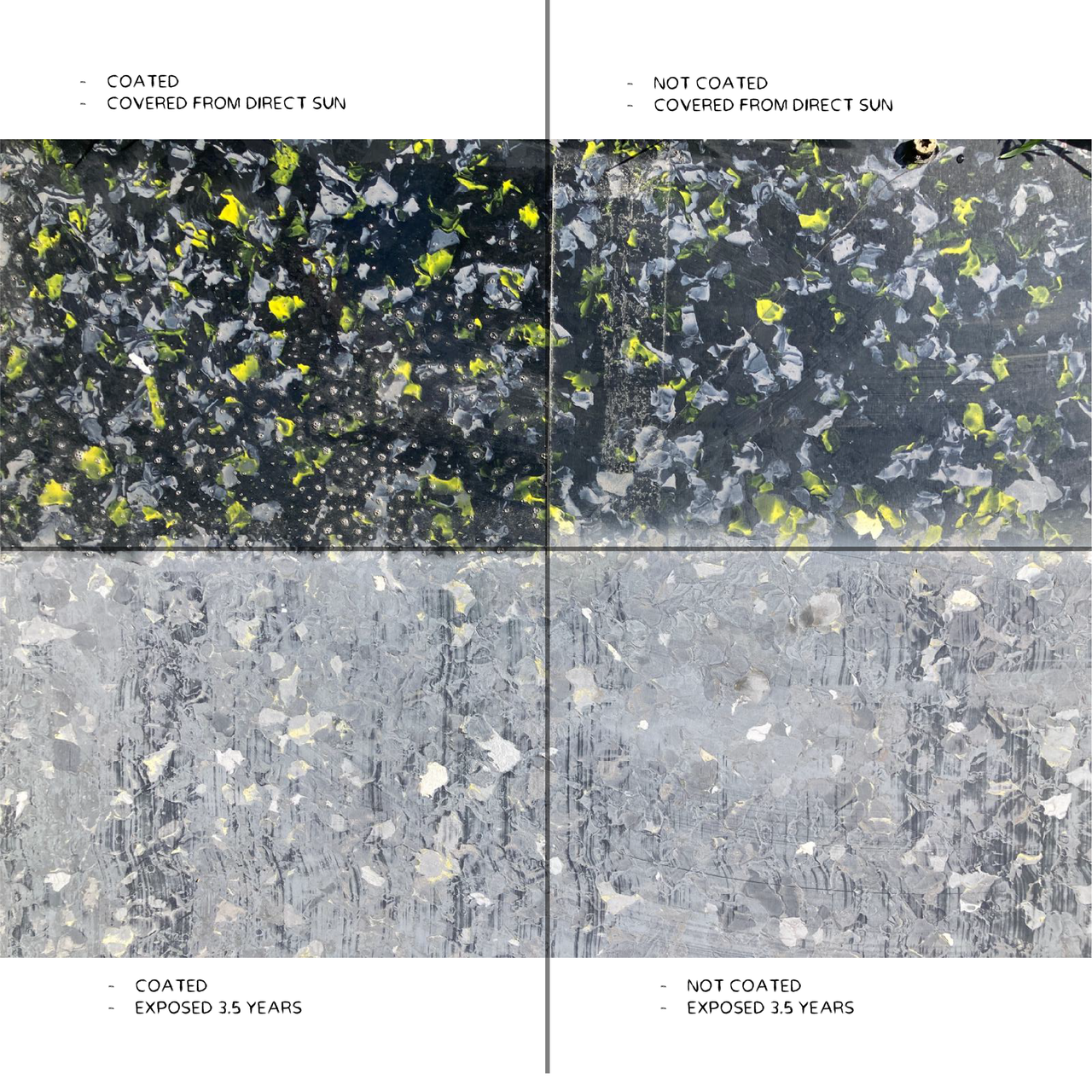

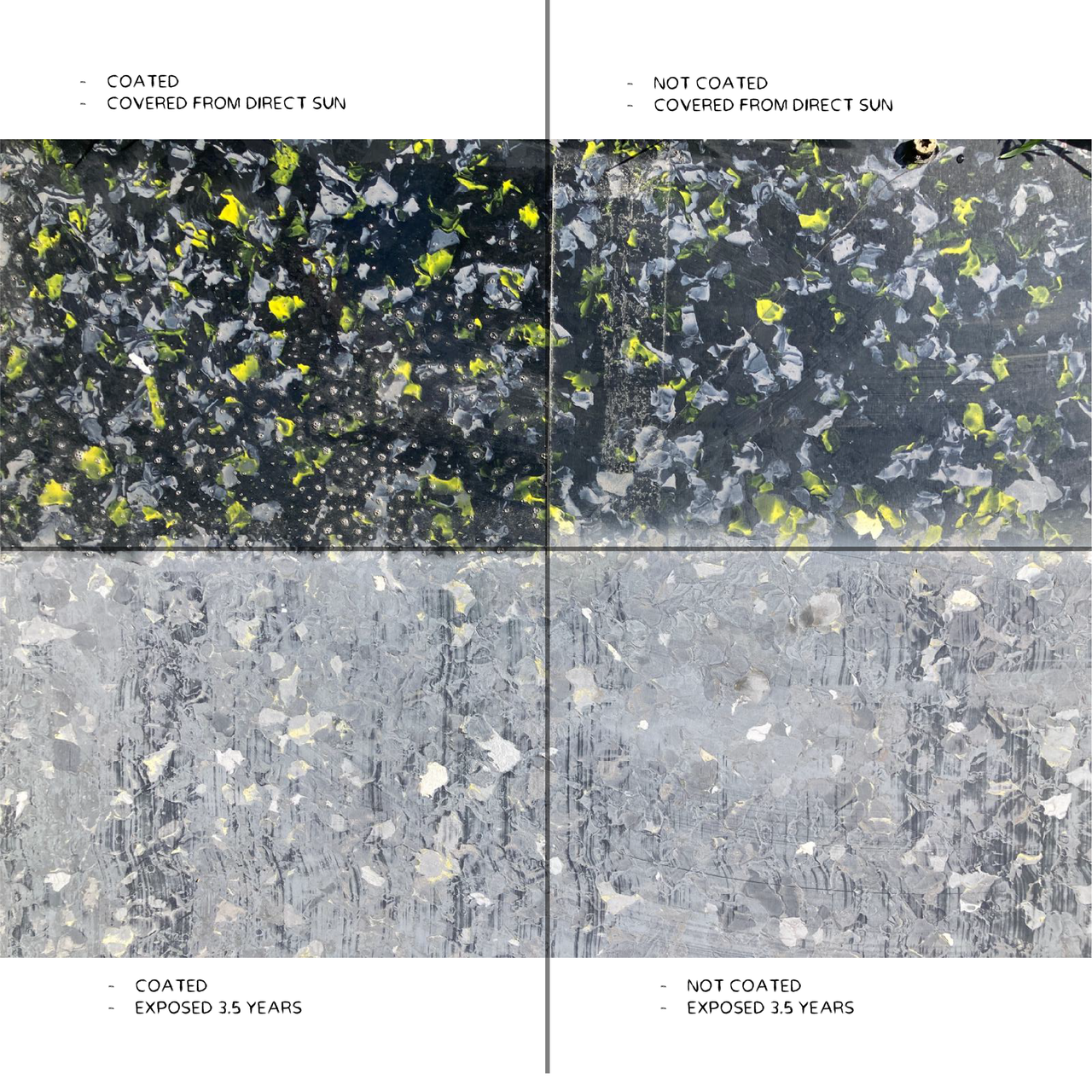

UV degradation after 3.5 years

This is the state of the top surface of our sheets after 3.5 years. The first photo shows a piece with 4 different samples and conditions on the same sheet.

We can see that the parts protected from sunlight are almost the same, but the parts exposed are degradated due to the UV exposure.

The coating we used to protect from UV is also gone in the exposed areas to UV and still good when is not exposed.

Overall seems that these recycled PP sheets:

- Get highly degradated when they are exposed directly to sun light

- Stay in good state when protected from direct sun light (See also the pictures from the bottom of the sheets)

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...