Can we make a roof from recycled aluminium cans?

ToolRecycled

More Information

Collection of the cans

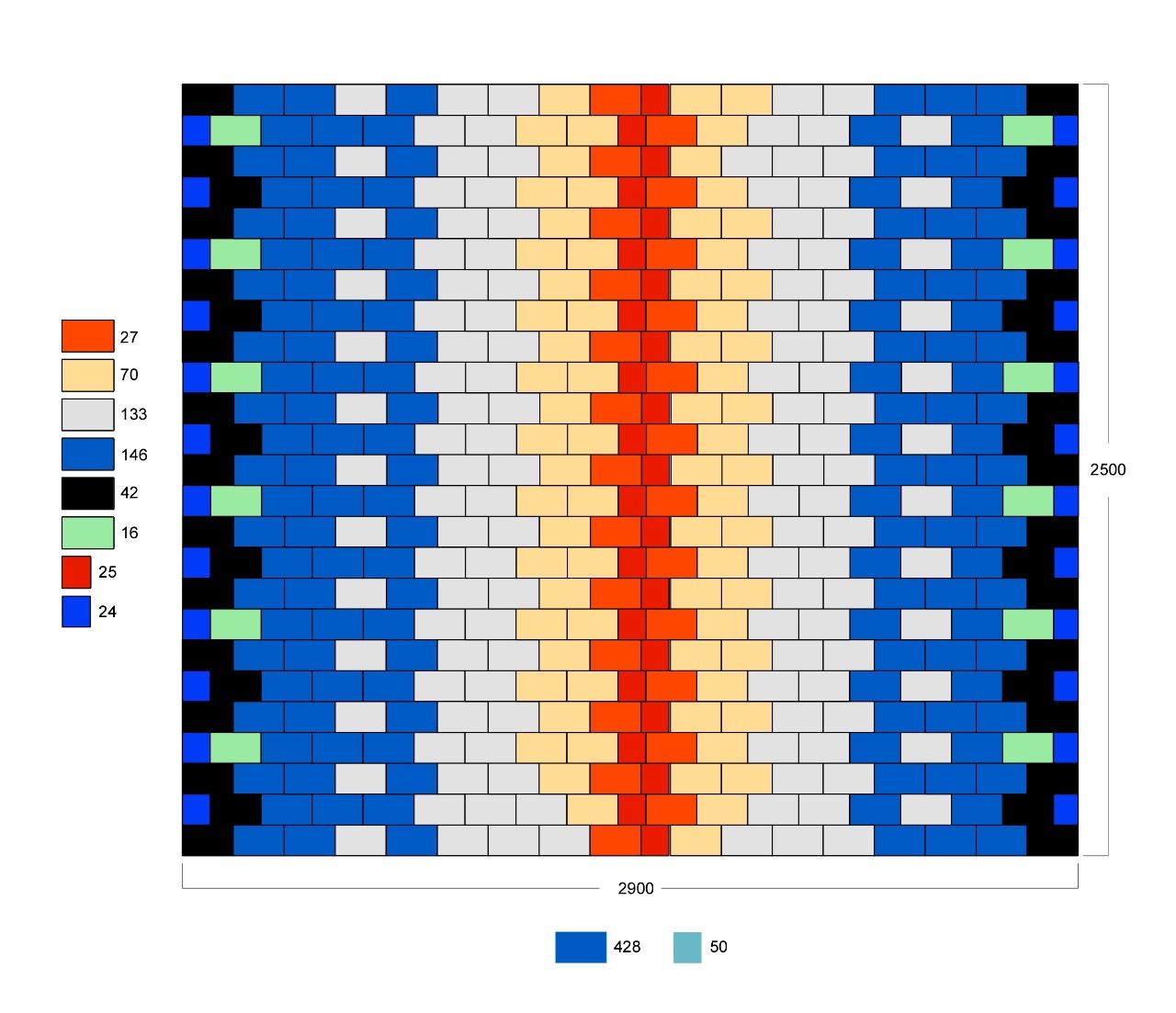

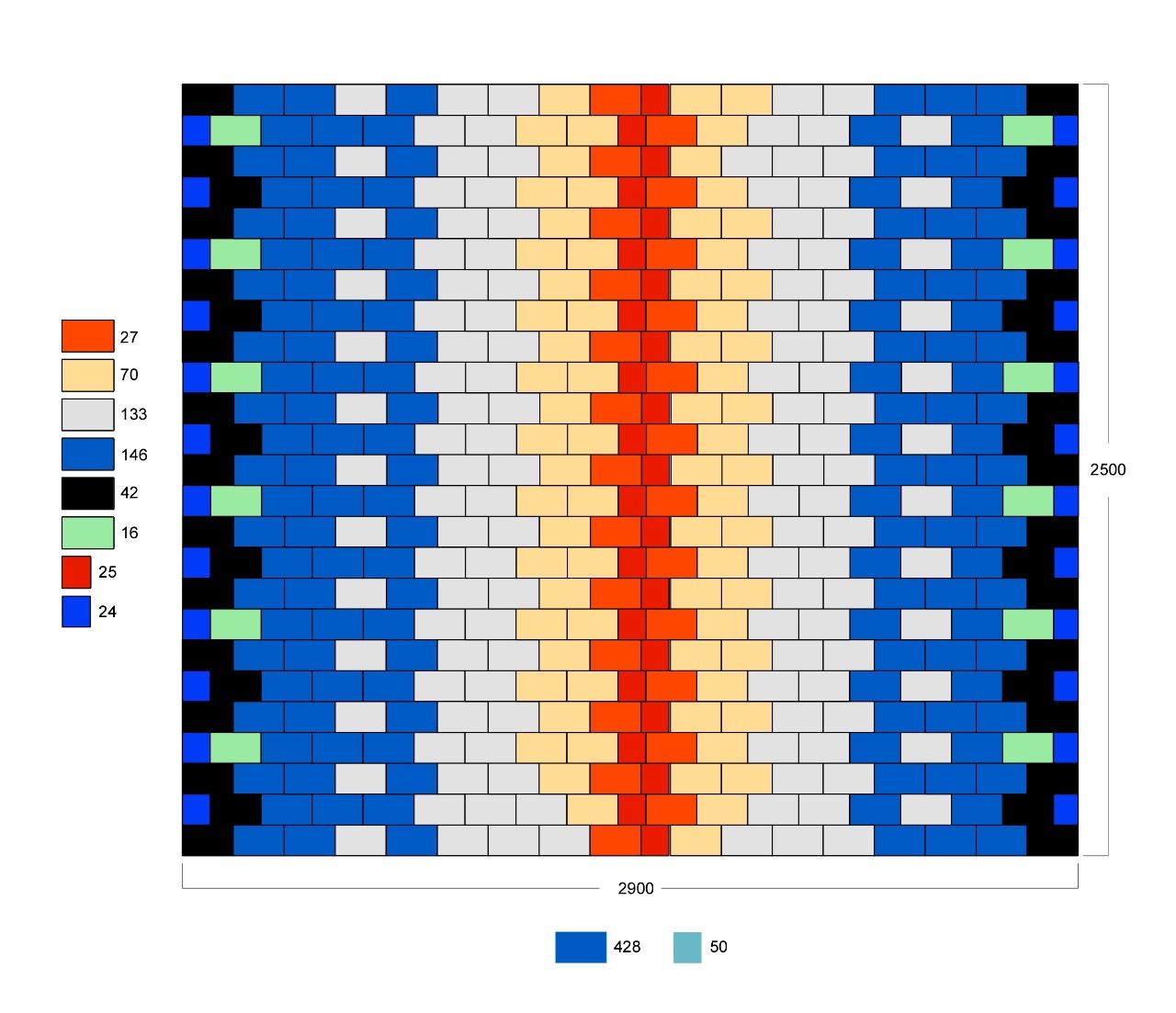

After counting, we will need more than 500pcs of cans to complete the roof size of (2.5x2.9m) 7.25sq/m, which is difficult to achieve by the consumption in the Kamp alone. So we made a poster to ask our neighbours to collect the cans with us.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Tool for opening the cans

The tool for opening the side of the can is modified from a market bought soda can opener(link below), the wooden part is added to make the cutting diameter wider.

https://www.amazon.com/Opener-Manual-Safety-Camping-Openers/dp/B0BKQMST9V/ref=sr_1_24?crid=23C010V2OPLUJ&keywords=Soda+can+opener&qid=1693305451&sprefix=soda+can+opener%2Caps%2C248&sr=8-24

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Designing the shape of the shingle

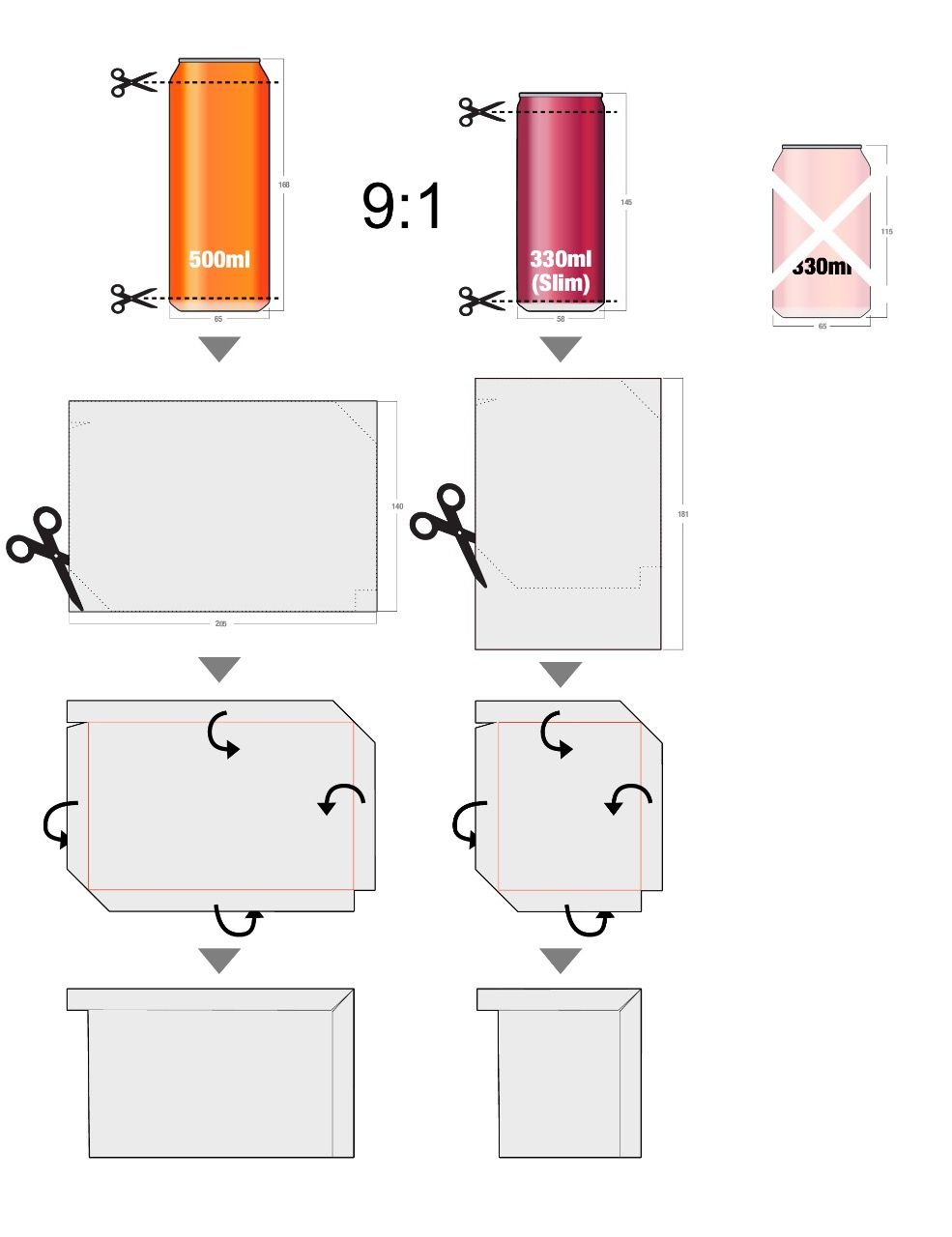

Out of the 3 most common sizes of the can in the market. 2 of them(500ml & 330 slim) seem to be quite popular among our neighbours. So we counted and measure the size that we will be using, then design the cut out. (Having 2 different sizes of shingles is not ideal because it creates unnecessary gaps and potential leakage spot, but we want to include most of the cans from different neighbours)

Loading...

Loading...

Prototyping

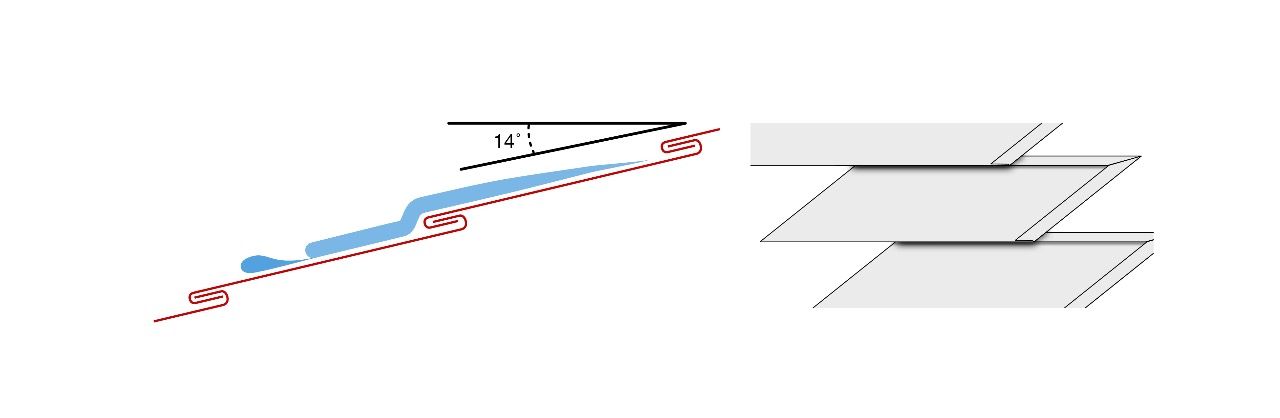

A small surface has been built to test the interlocking system, shingles are held in place by using the can to avoid drilling holes through the shingle. Rain flow were recreated under the shower.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Preparation

After more than a month of collecting, we finally have enough cans.

Based on the quantity and colours of the cans, we have decide to put them into a gradient pattern.

We have assembled a team to help doing the folding of the shingles.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

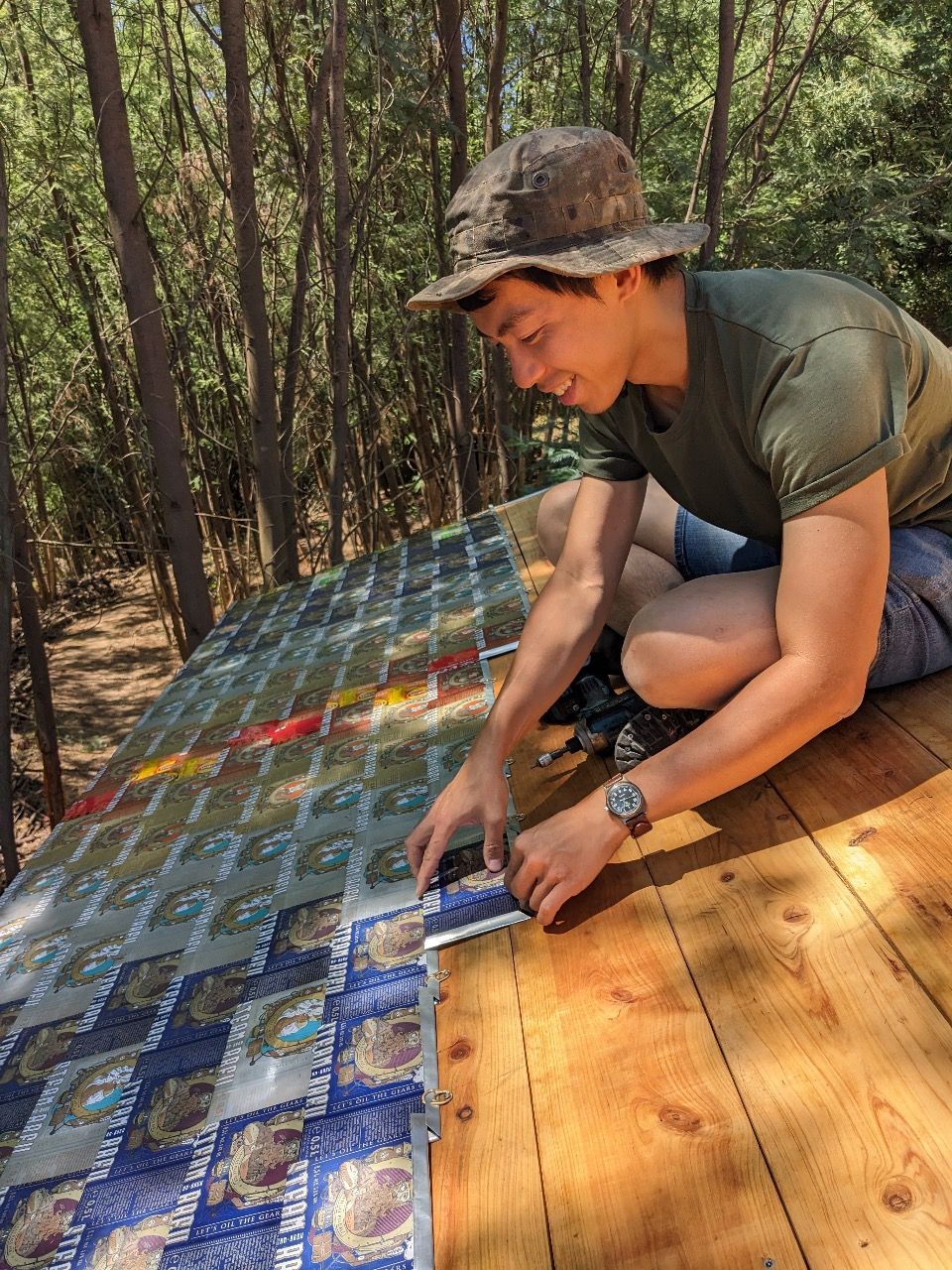

Start building

Created 2yCreated over 2 years ago

it took around 5 days to complete the roof, 498pcs of tiles in total

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

How to replace tiles on can roof?

in case of damaged tile, hope this would be helpful 😉

Diagonal can roof tiles

Created 1yCreated almost 2 years ago

a small roof has been build to try out to lay the tiles in a diagonal way.

Introducing the Can Slicer

The Can Slicer is a tool to slice open aluminium cans, turning them into flat sheets of metal for upcycling projects.

It allows the process of cutting to be more efficient, quick and easy.

Made of locally recycled HDPE with precious plastic machines from Fablab Tokwawan.

Available here: http://kevin-cheung.com/store/z87m4lktwkce2ahd8xy4vpod69yncf

3D drawing files also available for download.

The body can be 3d printed and the blade can be replaced by 10mm wide m3 spacer.

A quick and efficient way to die cut Aluminium sheet

Created 6moCreated 7 months ago

This is the journey of searching for the right machine, fitting it into a suitcase, making the process to be mobile.

Can roof after 1.5 years

After experiencing some intense rain and typhoon in Hong Kong,

the tiles so far holding up quite well with no leakage.

Discolouration can be seen on the area under the most UV light,

especially the color red faded the most quickly.

Zero maintenance so far 💪🏻

Aluminium Can roof two years later

Created 4moCreated 5 months ago

Here some pictures what the roof looks like 2 years later. All the shingles are pretty much in the same place and not much changed. A few trees fell on it so those that got hit are a bit more bended. The main difference is in the colors. Specially noticeable in the cocacola and lipton can. The whole roof looks a bit more greyish now

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...